TECHNOLOGY

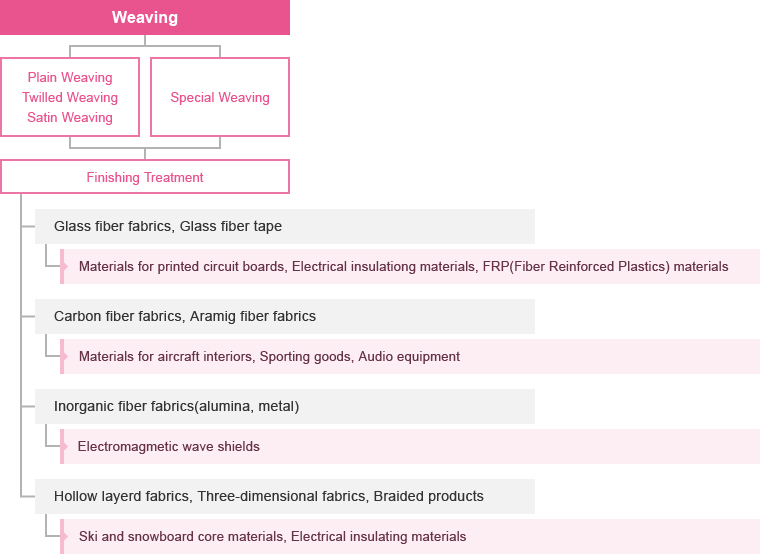

Technology / Weaving

Dreams to Reality

Everyone has dreams, and we at Arisawa have the technology and know-how to bring those dreams to life! Arisawa's expertise in materials manufacturing industry is renowned and has helped bring forth many new technologies. Arisawa pride ourselves on our many strengths: technological ability, quick and timely adjustments to changes in the world market, and most of all, our eagerness to accept and tackle new challenges. "We can do it!" and we want you to know that a relationship with Arisawa will bring your Dreams to Realty!

WeavingOur expertise in weaving is unsurpassed in the industry!

Reinforced molded plastics, made from fibers bonded with plastic resins, have many desirable properties. They are very strong, light weight, easy to use and have excellent resistance to corrosion and weathering. Our products are used in aircraft, spacecraft, medical applications, electrical insulation, building construction, desalination and purification of water, office and optical equipment, etc. The right combination and orientation of fibers and resins is selected for each application. In filament winding, fibers wet with resin are precision wound on properly shaped mandrels and cured. In pultrusion, groups of fibers are wet with resin and shaped and cured by pulling through a heated die. In press molding dry "prepreg" sheets are assembled and pressed into shape and cured in a heated press. The dry "prepreg" is made by treating a fabric with a liquid resin. The wet sheets are heated in an oven to dry the surface and partially cure the resin.