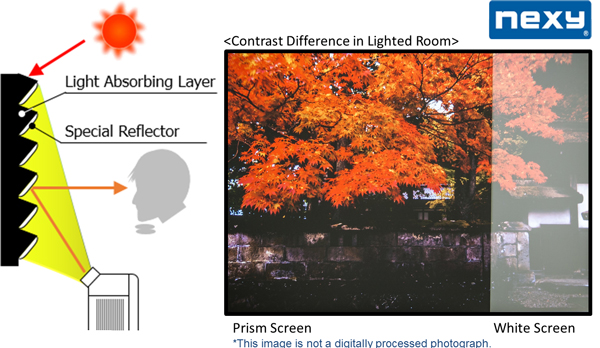

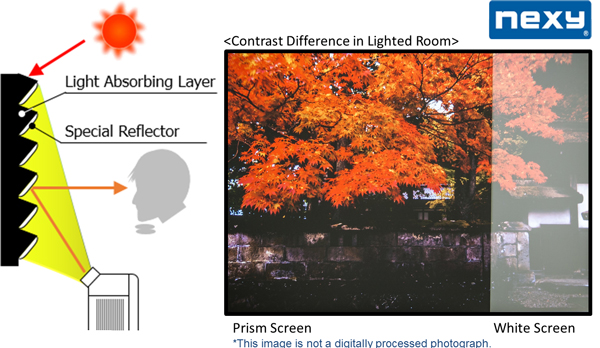

All our projection screens can use in a bright room with high contrast image. You can find the best suited projection screen for your projectors.

[Application] Home theater, Conference room, Karaoke, Theater, Education, etc.

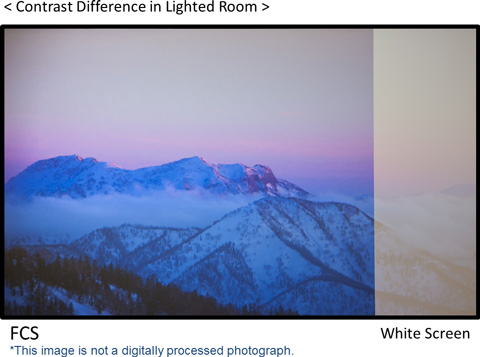

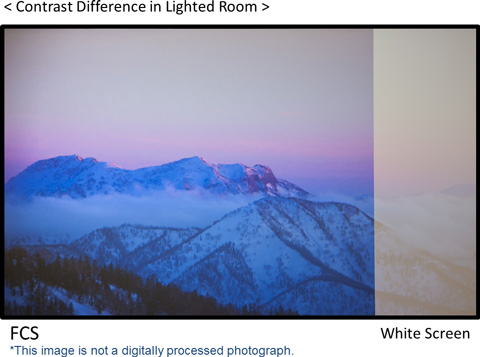

1) FCS( Fine Contrast Screen): It is suited for a standard projectors. |