[Application]

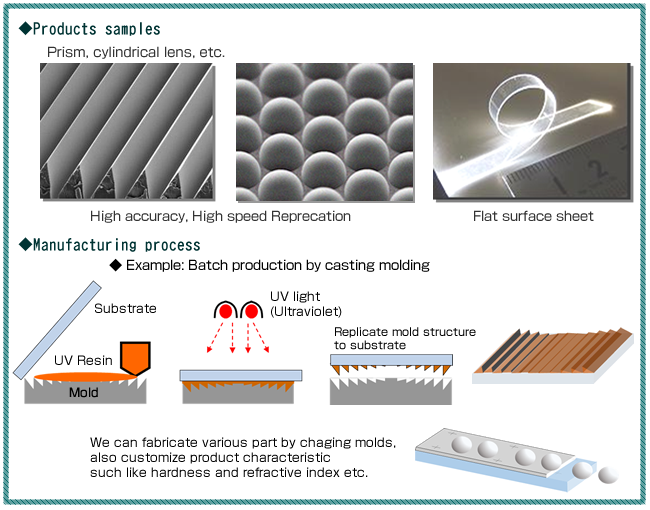

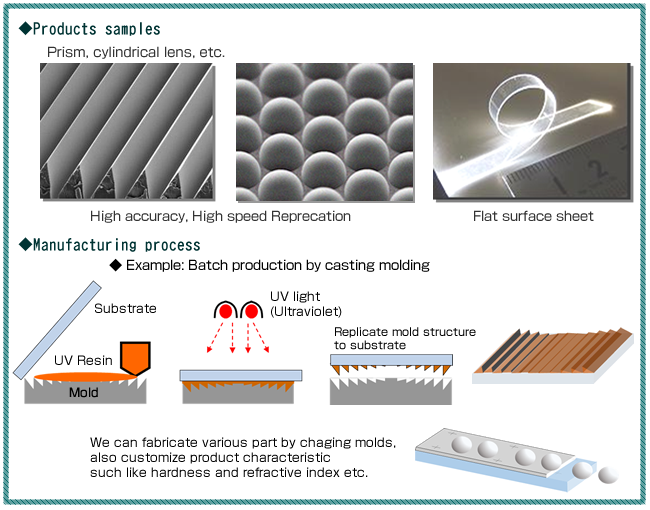

Fine pattern parts are developed in various industries such like buildings, medicals, telecommunications, lighting, energy, automobiles, etc. In optical applications, this technology is widely used for optical lens products as below - MLA, Fresnel lens, Diffracting grating, Lenticular lens sheet, Prism sheet, Moth eye lens, etc.

Please feel free to contact us.

[Feature]

i) Arisawa’s optical products are made with Arisawa original ultraviolet curable resins.

・Cast molding with batch production.

・In comparison to well-known Injection molding, this cast molding batch production has an advantage of saving costs on both the initial cost and the mold cost, therefore, we can provide products at relatively low cost from test production to mass production.

ii) Arisawa undertakes on manufacturing products using your mold.

・We can replicate molds from customers mold, silicon wafer, etc. and provide transfer molding products.

iii) Arisawa can make a copy of your mold.

・For risk avoidance from loss or damage of your valuable mold, we can also make a copy of a mold from your original and produce transfer molding products with the replica mold.

・We can also make multiple replica molds and join them to make a larger one.

It is effective for cost reduction in the mass production phase and contribute to lowering the price of transfer molding products.

iv) Arisawa can replicate ultrafine patterns on various substrates, glass plates, transparent plastic plates and films.

・Production is available from palm size up to maximum 1230mm X 1530.

Please feel free to contact us for details. |